Understanding the differences between industrial PCs and regular PCs is essential in the modern landscape of computing technology. An industrial PC is designed to operate in harsh environments that standard PCs cannot withstand.

Industrial environments often involve extreme temperatures, vibrations, dust and humidity, in sectors like manufacturing, defence, mining and transport.

Here’s what sets industrial PCs apart.

Durability and ruggedness

Performance in extreme conditions

Industrial PCs are built to perform reliably in extreme conditions, including high or low temperatures that would typically challenge or damage regular PCs. They feature efficient cooling systems and components designed to withstand significant temperature fluctuations, helping ensure consistent performance and a longer lifespan.

Longevity and compatibility

In industrial settings, consistency over long periods and compatibility are vital. Industrial PCs often have longer product life cycles and support legacy systems, ensuring seamless integration with existing technology. This contrasts with regular PCs, which prioritise newer technology and may phase out support for older systems more quickly.

Customisation and specialised components

Adaptability and expandability

The adaptability of industrial PCs is crucial in industrial applications. They often include options for additional serial ports, expansion modules or specialised input/output cards. Support for legacy software and peripherals is common. Regular PCs, while versatile, don’t typically offer the same level of expandability and are not as readily adaptable to specialised industrial tasks. This extra expandability and compatibility means Industrial PCs can often perform tasks and run programs that a regular computer can’t.

Applications of industrial PCs

The comparison between industrial PCs and regular PCs highlights a fundamental principle in technology: the need for specialised tools for specific tasks. Industrial PCs, with their durability, adaptability and longevity, are engineered to meet the demanding needs of industrial environments. They stand apart from regular PCs, which are designed for more controlled and less demanding settings. Understanding this distinction is crucial for professionals making decisions in industrial and technological landscapes.

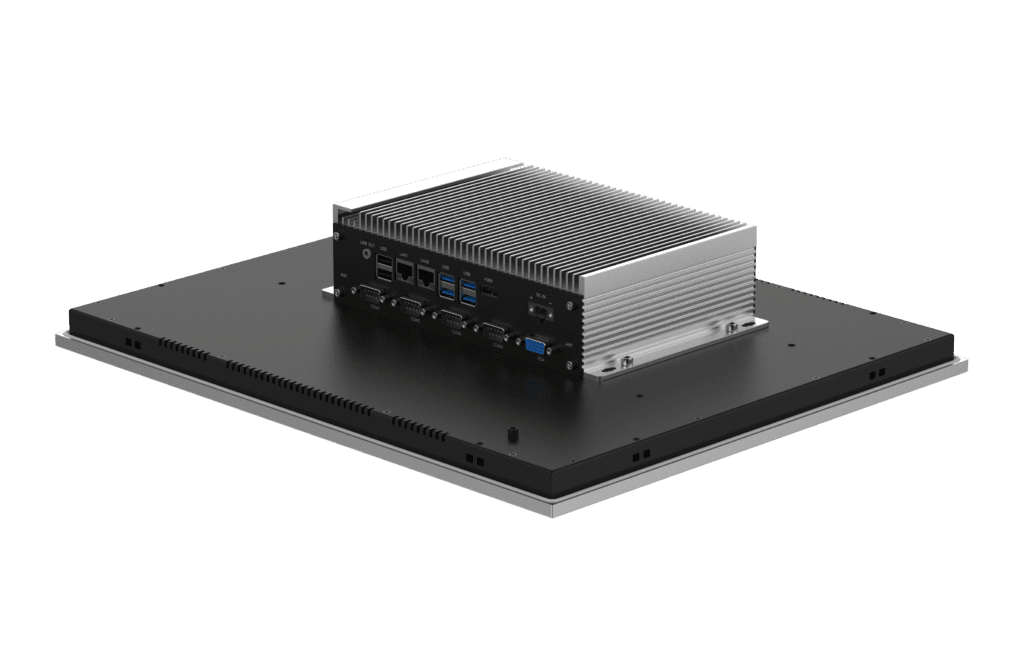

With decades of experience in industrial applications, Esis offers a range of industrial PCs, including rugged notebooks, panel PCs, and embedded systems, catering to the diverse needs of industries. Their expertise in engineering services ensures that these PCs are not only robust but also perfectly tailored to the specific requirements of their clients. Contact Esis today for your industrial computer needs!

FAQs

What is an Industrial PC?

An Industrial PC is a specialised computer designed for rugged environments, offering durability, reliability and enhanced performance compared to regular PCs.

How do Industrial PCs differ from Regular PCs?

Industrial PCs are built to withstand harsh conditions such as extreme temperatures, vibrations, and dust, while regular PCs are designed for everyday use in controlled environments. In addition, industrial PCs often include extra connectivity, expandability and legacy application support, making them ideal for industrial applications.

Why are Industrial PCs used in harsh environments?

Industrial PCs are equipped with rugged features like metal casings, fanless designs, wide temperature tolerance and robust components, making them ideal for challenging industrial settings where regular PCs would fail.

Can Industrial PCs handle high-performance tasks?

Yes, Industrial PCs can be engineered with powerful processors and ample memory to manage demanding industrial applications requiring real-time precision and high-speed processing.

What customisation options are available for Industrial PCs?

Industrial PCs offer scalability and can be customised with specific I/O capabilities, storage, and networking options to meet unique industrial requirements.

Are Industrial PCs more expensive than Regular PCs?

While Industrial PCs may have a higher initial cost, their long-term operational efficiency and durability often make them a cost-effective choice for industrial applications.

What types of connectivity options do Industrial PCs offer?

Industrial PCs provide advanced connectivity options including USB, Serial and Ethernet communications, industrial cellular modems, and wireless modules for seamless integration with industrial equipment.

How do security features in Industrial PCs compare to Regular PCs?

Industrial PCs are equipped with robust security features to protect sensitive data and operations, offering a higher level of security required in industrial applications compared to regular PCs.

Interested in upgrading to Industrial PCs? Request a custom quote from Esis and discover how our tailored solutions can enhance your operations.